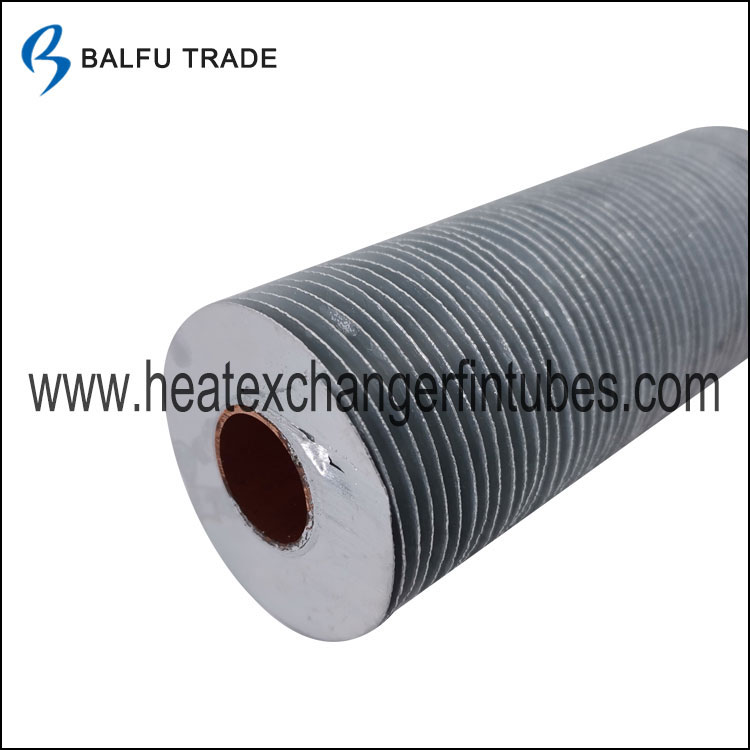

Extruded Fin Tube

Extruded fin tubes are a type of heat transfer component commonly used in heat exchangers and air-cooled heat sinks. They consist of a base tube with fins that are formed by an extrusion process. The fins are an integral part of the tube, created by pushing the material through a die to form the des......

Send Inquiry

Product Description

Extruded fin tubes are a type of heat transfer component commonly used in heat exchangers and air-cooled heat sinks. They consist of a base tube with fins that are formed by an extrusion process. The fins are an integral part of the tube, created by pushing the material through a die to form the desired fin shape.

Here are some key features and benefits of extruded fin tubes:

1. High Heat Transfer Efficiency: Extruded fin tubes are designed to maximize heat transfer efficiency. The extrusion process creates fins that have excellent contact with the surrounding fluid or air, allowing for efficient heat transfer. The extended surface area provided by the fins enhances the heat transfer coefficient and improves overall heat exchange performance.

2. Sturdy and Durable Construction: The fins on extruded fin tubes are formed from the same material as the base tube, resulting in a strong and durable construction. This makes them suitable for applications where mechanical strength and resistance to external forces are important, such as in air-cooled heat exchangers subjected to vibrations or in harsh operating conditions.

3. Enhanced Air Flow and Heat Dissipation: The fin design of extruded fin tubes promotes improved airflow and heat dissipation. The fins provide channels for the air to flow through, increasing the convective heat transfer between the tube and the surrounding air. This is particularly advantageous in air-cooled heat exchangers and heat sinks where efficient cooling is essential.

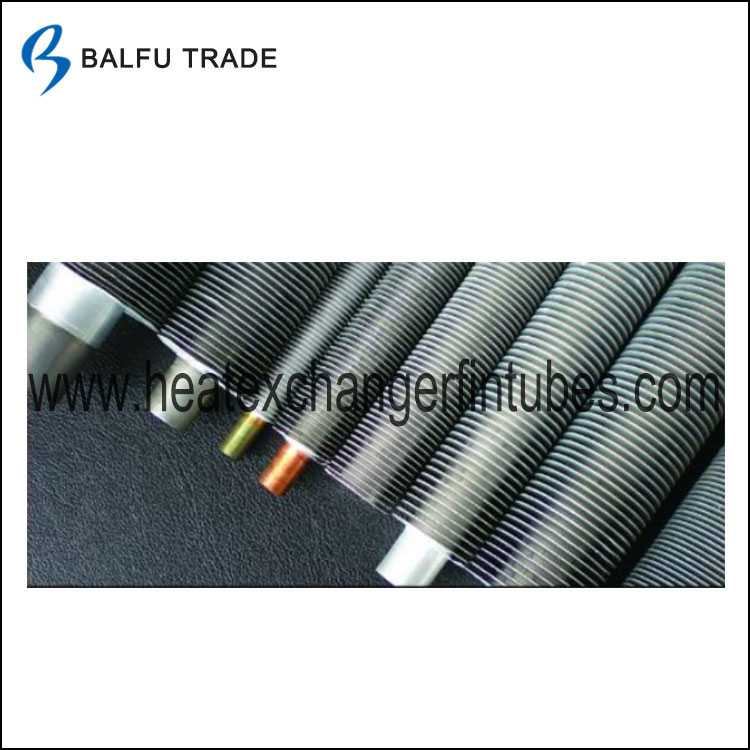

4. Wide Range of Fin Geometries: Extruded fin tubes can be manufactured with various fin geometries to meet specific heat transfer requirements. The fin shape, fin density, and fin height can be customized based on the application and desired performance. Different fin configurations, such as plain, serrated, or louvered fins, offer flexibility in optimizing heat transfer performance.

5. Corrosion Resistance: Extruded fin tubes can be made from different materials, including aluminum, copper, and stainless steel, depending on the application requirements. These materials are often selected for their corrosion resistance properties, ensuring the longevity and reliability of the fin tubes in corrosive environments.

6. Cost-Effective Solution: Extruded fin tubes offer a cost-effective solution for heat transfer applications. The extrusion process allows for efficient and high-volume production, reducing manufacturing costs. Additionally, the enhanced heat transfer efficiency of extruded fin tubes can contribute to energy savings and improved system performance, making them a cost-effective choice over the long term.

Extruded fin tubes are commonly used in applications such as air-cooled heat exchangers, air conditioning systems, refrigeration equipment, power generation, and process industries. Their robust construction, high heat transfer efficiency, and versatility make them suitable for a wide range of heat exchange applications.